NOTE:

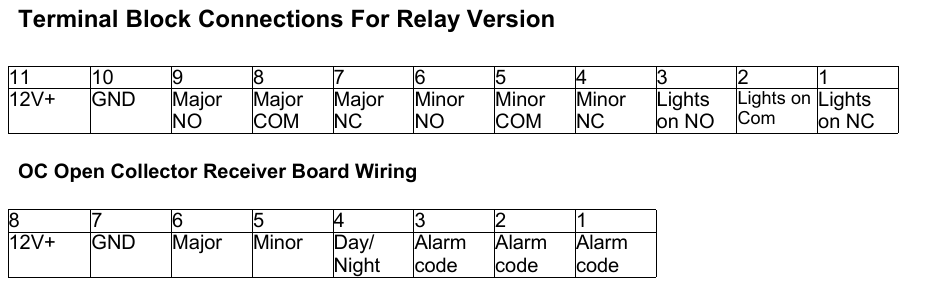

There are 1K alarm circuit terminations on the -OC version of this board - if they are not wanted simply remove the resistor network next

to the terminal bock at the top of the circuit board.

NOTE:

There are 1K alarm circuit terminations on the -OC version of this board - if they are not wanted simply remove the resistor network next

to the terminal bock at the top of the circuit board.The ITLMTM is a tower lighting alarm sensor system that monitors ’Red lighted’ towers (towers using incandescent bulbs in red lens housings). It detects 11 different alarm states including predictive failure alarms. The predictive alarms allow you to schedule tower maintenance before the failure actually occurs.

| Alarms are organized into three levels | |

|---|---|

| Alarm Type | Details |

| Day/night | for FCC/FAA required logging |

| Minor | failures requiring maintenance |

| Major | failures requiring FAA notification and maintenance. |

The system consists of a ’Sensor’ and a 'receiver'. This Sensor can be retro-fitted into the existing tower site’s lighting control panel. The 'receiver' normally mounts in the tower building and connects to the ‘Sensor’ via a custom modular shielded cable. The ITLMTM calibrates itself to your tower’s beacon and obstruction bulb sets with a simple push of a button.

Important: Installation should be preformed by a qualified electrician only! See safety section at end of this manual. Read this installation manual through once before starting the procedures.

The ITLMTM is intended for installation on single-phase (120V) red lighted towers. Unpacking will reveal a receiver circuit board, a

sensor circuit board, and a custom cable. This shielded and weatherproof cable comes cut to length with a core grip already installed

onto the sensor end. Its weatherproof and shielded jacket is thick and requires a special ratchet crimp tool to assemble. Pay extra

attention to polarity when assembling this cable (there is a definitely a difference between the sensor and receiver end). If your cable

is too short or damaged, we strongly recommend exchanging it with a factory assembled one.

First, familiarize yourself with Fig 1A. It shows a typical circuit where the Day/night switch controls L1 (line or hot-side) going to the side obstruction) lights and the flasher switch. The flasher switch provides the blinking action of the beacon circuit. Neutral provides the return path for the day/night, blinker and lamps.

Now, examine the tower site and identify the lighting control panel; it is usually at the bottom of the tower. First, shut off the power to the tower lights and verify that the power is off. Opening the panel will reveal a feed line from a circuit breaker panel. Identify L1, neutral and ground. There will also be a conduit or a SO style cable coming down the tower to enter the lighting control panel. This conduit will have three wires for a beacon and side light tower (occasionally there may be a fourth ground wire). One of these three wires is the neutral. The other two wires will be the line side of the beacon and side lights.

Now, determine if there is enough room to mount the Sensor circuit board in the lighting control panel. The beacon and side light wires will thread through the appropriate toroid. Make sure there is adequate clearance for wires and access to terminal block screws. To physically mount the Sensor Circuit board in the lighting control panel, first clean the mounting area with the alcohol wipe provided, then remove the backing from the “sticky feet” and press into place. <clear:all> Term-blocks.png

Note: All wires should be of the proper gage to comply with the REA electric codes.

As shown in Fig 1B, connect L1 from the circuit breaker panel, with a black wire of the same gage, to the terminal on the sensor board marked L1. Next, connect neutral from the circuit breaker panel, with a white wire of the same gage, to the terminal on the sensor board marked N. Next, identify the side light wire that comes from the tower and temporarily disconnect it. Thread it through the toroid marked ‘Side’. While reconnecting the side wire, add a black wire of the same size, and connect it to the terminal on the ‘sensor’ board marked ‘D/N’. Now, momentarily disconnect the beacon wire and thread it through the toroid marked ‘beacon’ and reconnect.

If possible, the modular cable should exit the lighting control panel from the bottom of the box to avoid any possible moisture entry. Plug the modular cable end with the core grip into the Sensor board. Finally, run the other end of the modular cable to the Fig 1B alarm panel site. Use a wrench to tighten the core grip to insure a good seal. At this point your circuit should look like figure 1B.

First, select a location that has easy access to battery backed up 12Vdc and the entry of the weatherproof cable. There are sticky feet to provide easy mounting of the receiver to any flat surface..

Connect the Custom Sensor cable to the jack in the lower left-hand corner of the receiver circuit board, this is the jack that DOES NOT have a silver warranty sticker covering it. The receiver board will have all three jumpers set as on the left side of the receiver board. If your tower does not have Beacon lamps (pairs of 620W or 735W bulbs) remove the shunt across the pins labeled ‘BCN’. If your tower does not have a Flasher on the beacon circuit, (it most probably does) then remove the shunt marked ‘FSH’. Finally, if your tower does not have side lights remove the shunt located by the label ‘SIDE’.

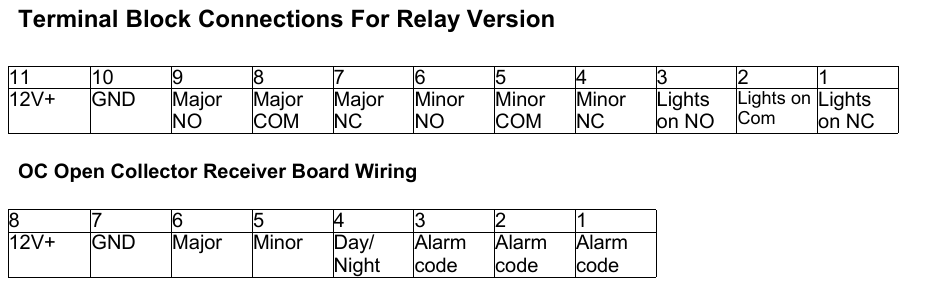

Wire the appropriate terminals from the receiver to your phone dialer, alarm panel or other equipment. The Relay version has relay outputs with separate commons for each output. The OC version (open collector) has pull down outputs that connect to ground in the advent of an alarm. It is not recommended connecting the alarm code outputs on the OC version as the additional information tends to confuse more than help.

NOTE:

There are 1K alarm circuit terminations on the -OC version of this board - if they are not wanted simply remove the resistor network next

to the terminal bock at the top of the circuit board.

NOTE:

There are 1K alarm circuit terminations on the -OC version of this board - if they are not wanted simply remove the resistor network next

to the terminal bock at the top of the circuit board.

Restore power to the tower. Verify that all the bulbs on the tower are working with an amp meter or by climbing the tower to see that the bulbs are lit. For the predictive alarms to work properly, the bulbs should be new at the time of calibration. Cover the day/night detector (with some black tape) to simulate nighttime. The green day/night LED should light. Press the small push button labeled “CALIBRATE” and hold until all of the LED’s flash once to indicate that the calibration has finished. If the trouble light is flashing or any other LED besides the green day/night is lit, please refer to the troubleshooting section (Appendix B).

You will need to wait more than 10 minutes for both the on and off response of the of day/night contact. The other alarm contacts have a one minute on delay. Now, remove the tape on the photo switch.

Note: There is no delay for LED indicators. During initial power up, LED’s flash on and off once. Flashing lights at other times represent a trouble code.

| Trouble report LED | |

|---|---|

| Number of Flashes | Meaning |

| 1 | Unit needs calibration |

| 2 | No day/night for over 20 hours (check photo-switch). Appears with beacon LED lit. |

| 3 | High current (shorted bulb) - Look for beacon or side light LED to find out which circuit. |

| 4 | DC is below 10 Volts. Check battery. |

| 5 | No AC - Check tower lighting circuit breaker |

| 6 | Consult factory |

| LED indicators | |

|---|---|

| LED | Meaning |

| Alarm enable | Power is applied between AC ‘com’ and Obstruction ‘hot’. If not on, all alarms are disabled except the 20 hour off alarm and low DC alarm. |

| Beacon | Beacon is enabled AND power is on AND one or more lights in beacon loop have failed open or hi-current. |

| Flash | Flash fail is enabled AND beacon remains on 10 Sec AND power is on. |

| Side | Power is ON AND side lights have been enabled AND one or more side lights have failed open or hi current. |

| Enable Jumpers - Allows for enabling and disabling various alarms. | ||

|---|---|---|

| Jumper name | On | Off |

| enables beacon alarms |disables beacon alarms | ||

| enables flash alarm|disables flash alarm | ||

| enables obstruction alarms|disables obstruction alarms | ||

Incandescent lamps sometimes give hints that they are about to fail. Lamps fail in two general ways; they burn out or they short out (and then burn out rapidly). As a bulb ages, the tungsten filament “boils off” atoms and becomes thinner and thinner. This thinning lowers the power consumption until the filament opens. Extreme thinning is reported as a lamp out. If you get such an alarm, you will still see all lamps lit. Recalibrating will cancel the alarm, but if the lamps have been in service for a long time, it would be wise to re-bulb at this time.

When a filament opens, sometimes as it wiggles it can weld itself back together, forming a high current bulb. The lamp will light brightly but for only a short time. We call this a high current failure. Recalibrating will cancel this alarm also, but measure the current to make sure it is in range of the wiring and alarm sensors capabilities.

If a bulb goes beyond the normal operating ‘envelope’, yet is still working, we call this a ‘predictive failure’. This information can allow you to perform re bulbing in good weather. You should always replace such bulbs as soon as possible. Now for the down side. Not every bulb gives a hint that it’s about to quit. More often than not, lamps fail suddenly.

If Beacon LED flashes on and off, and perhaps intermittent alarms the problem is most likely a Bad flashing unit. Lamps are not turning all the way off. Beacon must have less than 1 Amp during dark part of flash - replace.

| Top Page | wiki Index |

This information may have errors; It is not permissible to be read by anyone who has ever met a lawyer.

Use is confined to Engineers with more than 370 course hours of electronic engineering for theoretical studies.

ph +1(785) 841-3089

(C) Copyright 1994-2017, Transtronics, Inc. All rights reserved

Transtronics® is a registered trademark of Transtronics, Inc.

All trademarks are the property of their respective owners.